The bearing of the bearing is required for the bearing of the bearing

The shingle is actually a scraped surface, usually the inner surface of the hole, the purpose of which is to improve the contact condition, to generate the small concave point and to improve the lubrication. Scraping the requirements of the bearing should be treated according to the practical situation, due to various conditions, such as spindle speed, load, load direction and different purposes of, the tile requirements are different, such as grinding machine grinding head requires high accuracy high speed, so the scraping requires high point density, circular point uniform configuration, scraping to deep pits, rear axle assembly between 0.010 to 0.025, beating flexible rotation, slightly damp feeling, running 2 hours should not exceed 60 degrees temperature.

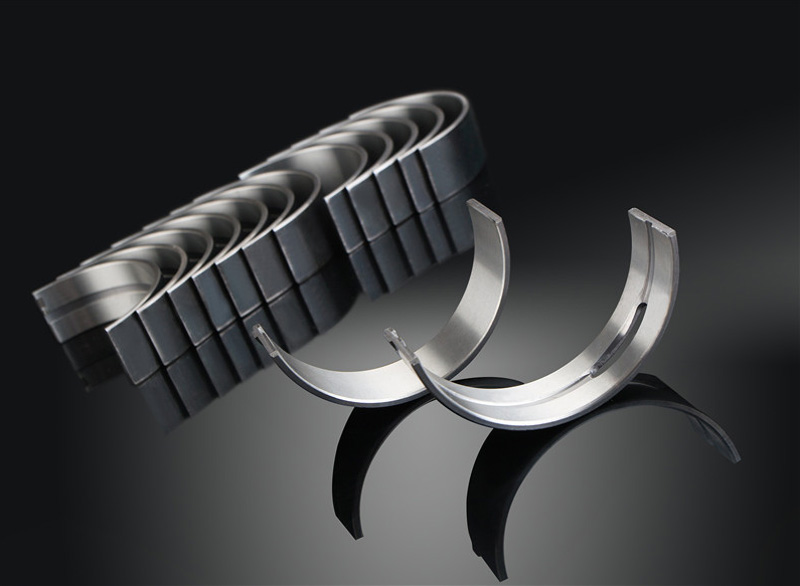

The spindle tile

Bearing bush for sliding bearing

The triangular scraper or the snake head scraper, if the axle hole is bigger and can be disassembled, it can also be used to pull the wheelset with a special pull scraper to pull the job. After each shave, it is better to remove the scraping burrs, especially the steel parts.

Actually real operations or to optimize the scraping, according to the specific circumstances such as similar lathe spindle, due to the radial load is always on one side, so the scraping can be interested in the point on one side of the bearing load when blowing some darker in colour, but on the other side, there was some shallow can even very pale, gradually in the middle of excessive, in this case, so we can ensure the accuracy of the longer use and longevity. In a word, it is necessary to have experience to be in a pattern, which includes mechanical structure, force analysis, cutter grinding and so on.

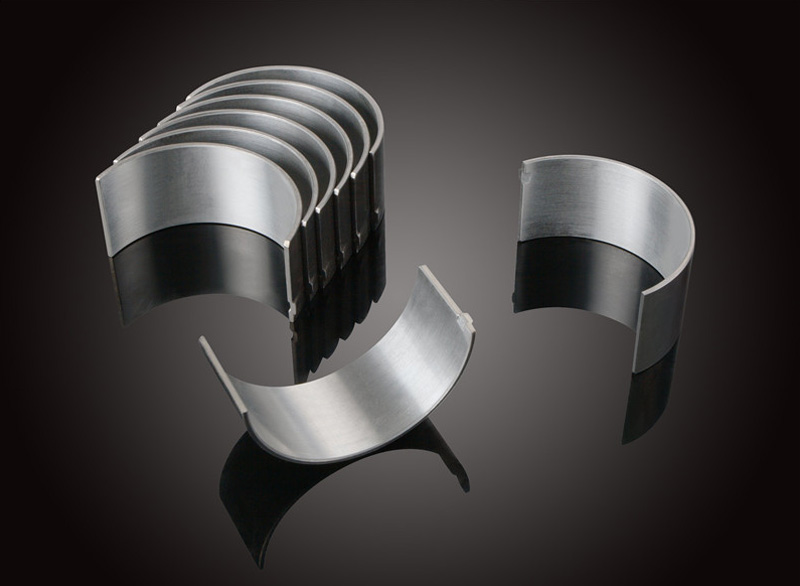

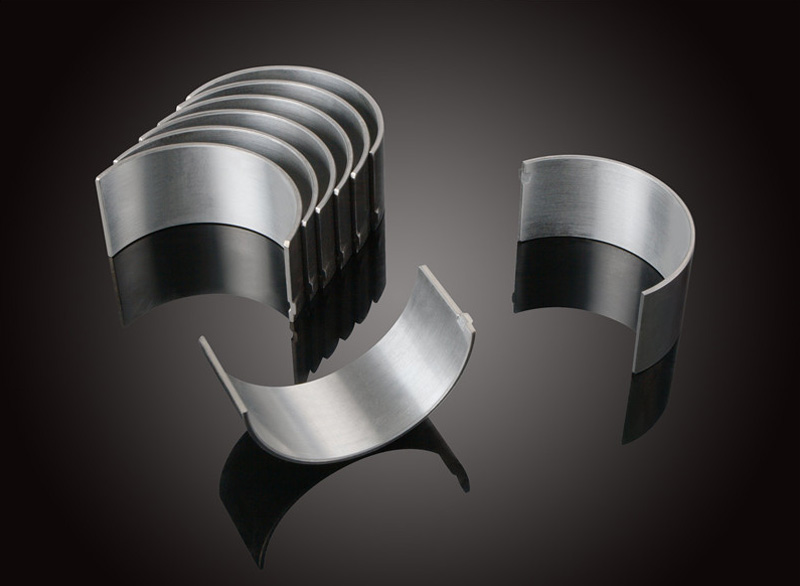

Before not updated technology, the industry generally believe that the engine crankshaft bearing, connecting rod bearing a new bearing shell must scraping, don't cut bearing does not guarantee good contact surface, even the scraping bearing shell as the top technology of auto repair. And modern automobile, especially small motor, its crankshaft bearing and connecting rod bearing, bearing the wear-resisting alloy coating is very thin, will not allow to be scraped, can only press corresponding dimensions to match. If there is no suitable size of curved bearing, it is necessary to grind the crankshaft with the method of the base hole to find the proper fit clearance.

The contact requirements of the bearing and the tile and the tile

(1) force bearing shell. Force bearing bush back to watts of the contact area should be greater than 70%, and uniform distribution, the scope of its contact Angle of a should be greater than 150 °, the rest are allowed clearance clearance b is not greater than 0.05 mm. See figure 1.

(2) not force bearing with tiles should be greater than 60%, the contact area and uniform distribution, the scope of its contact Angle of a should be greater than 120 °, allowing the parts have clearance interval b, should be no greater than 0.05 mm. See figure 1.