Analysis and judgment of the abnormal sound of the engine bearing

When the diesel engine is operating normally, its sound is rhythmic, uniform exhaust sound and slight noise, with certain regularity. When the parts of the diesel engine are not properly adjusted due to wear and tear or due to repair, they can break the clearance of the auxiliary, and there will be abnormal sound, such as abnormal tapping and firing sound. There was a sound when the diesel engine, should be based on the fault phenomenon, to analyze the causes of noise, find out the sound of parts, so as to timely take effective measures to exclude, to prevent malignant accidents. Damage to spare parts and release of the noise, should be repaired and replaced. The noise caused by excessive clearance shall be adjusted, repaired or replaced.

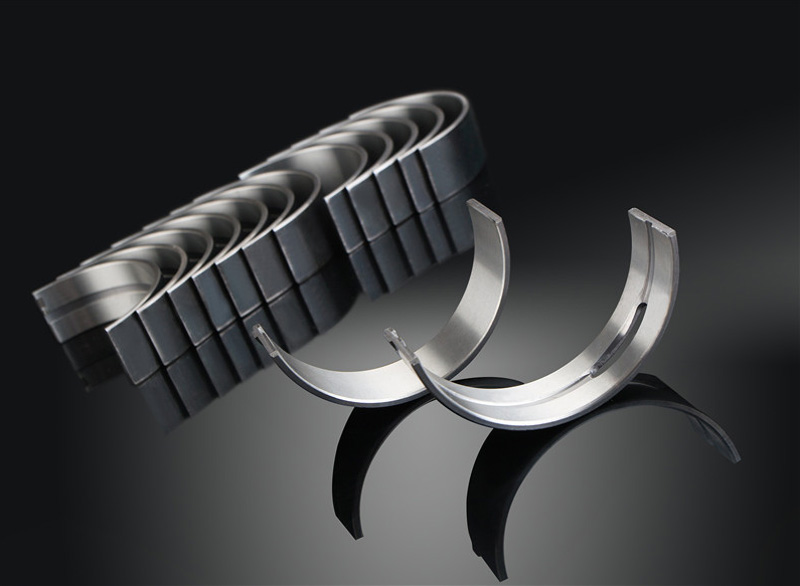

1. The connecting rod bearing is different

1. The phenomenon of

(1) when the diesel engine is idle, it makes a clear tapping sound on the upper part of the cylinder, which sounds like a small hammer hitting the "clatter" of the cement floor.

(2) the noise is obvious at low speed, and the noise is increased at high speed.

(3) when the cold car is loud and loud, the noise of the hot car is weakened or lost.

(4) after the cylinder "broke the cylinder", the sound diminished or disappeared.

2. why

(1) the gap between the piston and the cylinder wall is too large, and the piston swings into the cylinder wall and makes a noise. (2) the lubrication condition of cylinder wall is not good, and the piston skirt and cylinder wall are wiped (cylinder). (3) the gap between the piston and valve is too small (the clearance is too small), the piston top taps the bottom of the valve head. (4) the gap between the connecting rod bearing is too large, the piston rod assembly reciprocates, and the piston top taps the bottom of the valve head. (5) the connecting rod is bent, and the piston skirt and the cylinder wall are erased (the cylinder). (6) the valve springs are broken, and the valve is in collision with the top of the piston. (7) the surface of the cylinder cover is too thin (the compression clearance is too small) and the piston top is colliding with the bottom of the valve head. The valve breaks (turns) and the valve head drops the cylinder and the piston.

3. Check the judgment

(1) when it is cold, it is obvious that the hot car disappears into the cylinder wall of the piston, because of the excessive clearance between the cylinder and the piston. (2) at low speed, it is obvious that the noise in the high speed can be hit by the piston and valve, because the compression clearance is too small, or the surface of the cylinder head is grinding too much. (3) if you hear the "just" sound, it seems that the sound caused by a small hammer tapping the steel pipe is caused by the poor lubrication of the cylinder wall.

4. Fault handling

(1) according to the wear of the piston skirt and cylinder liner, the tank shall be re-pressed. (2) to wear the connecting rod journal or replace the shaft of the connecting rod according to the wear of the link. (3) if the valve sinks less, it can rehinge the valve seal belt and adjust the valve sinking. (4) visual oil pressure

Force, flow situation adjustment machine oil pump or change oil.

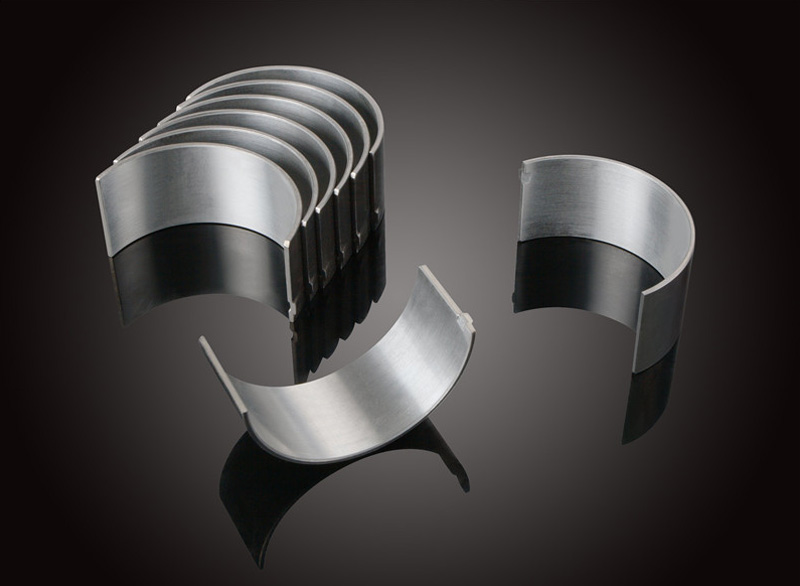

The engine crankshaft is different

1. The phenomenon of

The crankshaft warping is a heavy, stuffy percussion, which is more boring than the connecting rod bearing. The higher the engine, the higher the sound. When the engine speed and the sudden decrease of the engine speed, that is, the continuous sound; When the gas pedal suddenly increases, the sound is more prominent, the engine has the load or the start, the sound is obvious; The engine temperature changes without change.

2. why

(1) the crankshaft bearing and crankshaft journal wear out, resulting in excessive clearance and impact noise. (2) the retaining bolt of the bearing cap is loose, or the crankshaft bearing moment of the crankshaft is not up to the specified value when installed, and the impact of the shaft neck and the shaft is shown. (3) the crankshaft axial clearance is too large, resulting in the movement of the crankshaft before and after the crankshaft, which makes the crankshaft axial position and the thrust washer collide with each other. (4) the crankshaft bends and breaks down, and the sound is generated when running. (5) the oil channel is blocked, the shaft neck and the oil supply of the oil are insufficient or too thin and the friction is too hot, which causes the bearing alloy to burn off.

3. Check the judgment

(1) open the oil filler cap and listen to the sound with ear. If there is a dull, dull and heavy "clang, wok" sound, it can be judged that the crankshaft is broken; You can hear it when you're in the car. Stethoscope and, in turn, contact crankcase on each crankshaft tile near the hole, change the engine speed, when suddenly accelerated or suddenly slow down, if you can hear the sound of heavy, the crankshaft can be diagnosed with tile.

(2) in general, the crankshaft tiles ring, short circuit with the starter, and sometimes the sound can be reduced. It is usually empirically based on the position of the voice to determine which one is different. Also can use the single cylinder break fire method, the hearing sound if not change, and use the next two cylinder broken fire method test, the sound is obviously reduced, then the acoustic failure is between these two cylinders.

(3) the crankshaft cavitation or loss of the crankshaft is not only increased during the increase of engine speed, but also the vibration of the body. The radial clearance of the crankshaft tile or journal is too large, and the oil pressure is reduced while the noise is being made. The oil gauge indicates that the reading is not sufficient.

(4) when high-speed operation, the body has a larger vibration, vehicle load grade, bridge vibration, a significant reduction in the oil pressure, shows the crankshaft bearing gap is too big, alloy fall off.

(5) when the engine temperature is higher (the lower the oil viscosity) the sound becomes more obvious, and the sound becomes chaotic at high speed, then it can be curved.

(6) after determining the crankshaft tiles, remove the oil pan and remove the doubtful crankshaft tiles and check the condition of the crankshaft tiles. If ablation should be replaced; If the shaft alloy is good, apply appropriate thickness of thin copper skin, check the gap between axle and shaft neck. If the gap exceeds the limit of use, new parts should be replaced.

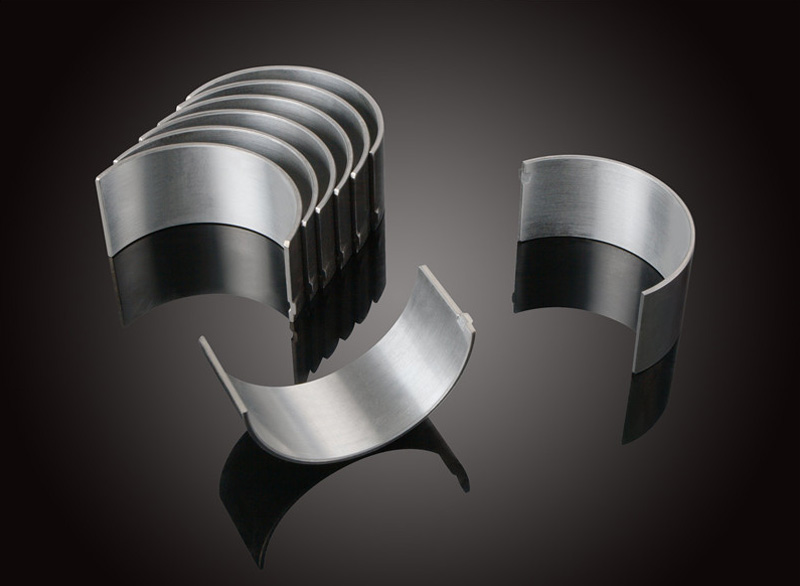

Different rings of camshaft axle

1. The fault phenomenon

The camshaft is a stuffy sound, but a bit more sharp than a crankshaft.

2. The cause of the problem

The CAM shaft and the shaft neck gap are too loose. Ablation, flaking or abrasion of CAM bearing alloy; The camshaft axial clearance is too large and the adjustment is improper; Camshaft bending deformation.

3. Diagnosis and treatment

The long screwdriver head is touched in the block of the block CAM, and the ear is attached to the starter to listen carefully. The engine speed can be changed repeatedly, and the vibration can be felt. When the camshaft axial clearance is too large, if it accelerates suddenly, the camshaft will ring out of the larger axis, which can be heard at the front of the car. Replacement should be given if the bearing is ablative and loose and the noise is too large. If the axial clearance is improper and abnormal, the inspection and adjustment should be taken.